据了解,这种食品酶是Danisco US Inc.使用转基因地衣芽孢杆菌(Bacillus licheniformis)DP‐Dzr50菌株生产的,旨在用于蒸馏酒精生产、生产葡萄糖浆的淀粉加工、烘焙和酿造过程中。经过评估,评估小组得出结论,这种食品酶在预期使用条件下不会引起安全问题。

根据申请人提交的申请,拟申请授权将该食品酶以以5.07mg TOS/kg面粉的最大建议使用限量用于酿造、蒸馏酒生产、葡萄糖浆生产过程中。

经过安全评估,膳食暴露于食物酶-总有机固体(TOS)的使用量为每天80mg TOS/kg bw,未观察到不良反应水平,该食用酶在预期的使用条件下不会引起安全问题。

更多详情参见:

https://efsa.onlinelibrary.wiley.com/doi/10.2903/j.efsa.2020.5972

Abstract

The food enzyme maltogenic amylase (glucan 1,4‐α‐maltohydrolase; EC 3.2.1.133) is produced with the genetically modified Bacillus licheniformis strain DP‐Dzr50 by Danisco US Inc. The production strain of the food enzyme contains multiple copies of a known antimicrobial resistance gene. However, based on the absence of viable cells and DNA from the production organism in the food enzyme, this is not considered to be a risk. The food enzyme is intended to be used in distilled alcohol production, starch processing for the production of glucose syrups, baking and brewing processes. Since residual amounts of the food enzyme are removed by distillation and starch processing, no dietary exposure was calculated for these processes. based on the maximum use levels recommended for baking and brewing and individual data from the EFSA Comprehensive European Food Database, dietary exposure to the food enzyme–Total Organic Solids (TOS) was estimated to be up to 0.199 mg TOS/kg body weight (bw) per day. Genotoxicity tests did not raise a safety concern. The systemic toxicity was assessed by means of a repeated dose 90‐day oral toxicity study in rats. The Panel identified a no observed adverse effect level of at least 80 mg TOS/kg bw per day which, compared to the estimated dietary exposure, results in a margin of exposure of at least 400. Similarity of the amino acid sequence to those of known allergens was searched and three matches were found. The Panel considered that, under the intended conditions of use, the risk of allergic sensitisation and elicitation reactions by dietary exposure can be excluded in distilled alcohol production and is considered to be low in starch processing, baking and brewing. based on the data provided, the Panel concluded that this food enzyme does not give rise to safety concerns under the intended conditions of use.

1 Introduction

Article 3 of the Regulation (EC) No 1332/20081 provides definitions for ‘food enzyme’ and ‘food enzyme preparation’.

‘Food enzyme’ means a product obtained from plants, animals or micro‐organisms or products thereof including a product obtained by a fermentation process using microorganisms: (i) containing one or more enzymes capable of catalysing a specific biochemical reaction; and (ii) added to food for a technological purpose at any stage of the manufacturing, processing, preparation, treatment, packaging, transport or storage of foods.

‘Food enzyme preparation’ means a formulation consisting of one or more food enzymes in which substances such as food additives and/or other food ingredients are incorporated to facilitate their storage, sale, standardisation, dilution or dissolution.

Before January 2009, food enzymes other than those used as food additives were not regulated or were regulated as processing aids under the legislation of the Member States. On 20 January 2009, Regulation (EC) No 1332/2008 on food enzymes came into force. This Regulation applies to enzymes that are added to food to perform a technological function in the manufacture, processing, preparation, treatment, packaging, transport or storage of such food, including enzymes used as processing aids. Regulation (EC) No 1331/20082established the European Union (EU) procedures for the safety assessment and the authorisation procedure of food additives, food enzymes and food flavourings. The use of a food enzyme shall be authorised only if it is demonstrated that:

- it does not pose a safety concern to the health of the consumer at the level of use proposed;

- there is a reasonable technological need;

- its use does not mislead the consumer.

All food enzymes currently on the EU market and intended to remain on that market, as well as all new food enzymes, shall be subjected to a safety evaluation by the European Food Safety Authority (EFSA) and an approval via an EU Community list.

The ‘Guidance on submission of a dossier on a food enzyme for evaluation’ (EFSA, 2009a) lays down the administrative, technical and toxicological data required.

1.1 Background and Terms of Reference as provided by the requestor

1.1.1 Background as provided by the European Commission

only food enzymes included in the EU Community list may be placed on the market as such and used in foods, in accordance with the specifications and conditions of use provided for in Article 7 (2) of Regulation (EC) No 1332/2008 on food enzymes.

Five applications have been introduced by the company “Danisco US Inc” for the authorisation of the food enzymes Alpha‐amylase from a genetically modified strain of Bacillus licheniformis (DP‐Dzb52), Glucan 1,4‐alpha‐glucosidase from a genetically modified strain of Trichoderma reesei (DP‐Nzh49), Glucan 1,4‐alpha‐maltotetraohydrolase from a genetically modified strain of Bacillus licheniformis (DP‐Dzr46), Glucan 1,4‐alpha‐maltohydrolase from a genetically modified strain of Bacillus licheniformis (DP‐Dzr50) and Glucan 1,4‐alpha‐glucosidase from a genetically modified strain of Trichoderma reesei (DP‐Nzh34).

Following the requirements of Article 12.1 of Commission Regulation (EC) No 234/20113implementing Regulation (EC) No 1331/20082, the Commission has verified that the five applications fall within the scope of the food enzyme Regulation and contain all the elements required under Chapter II of that Regulation.

1.1.2 Terms of Reference

The European Commission requests the European Food Safety Authority to carry out the safety assessments on the food enzymes Alpha‐amylase from a genetically modified strain of Bacillus licheniformis (DP‐Dzb52), Glucan 1,4‐alpha‐glucosidase from a genetically modified strain of Trichoderma reesei (DP‐Nzh49), Glucan 1,4‐alpha‐maltotetraohydrolase from a genetically modified strain of Bacillus licheniformis (DP‐Dzr46), Glucan 1,4‐alpha‐maltohydrolase from a genetically modified strain of Bacillus licheniformis (DP‐Dzr50) and Glucan 1,4‐alpha‐glucosidase from a genetically modified strain of Trichoderma reesei (DP‐Nzh34) in accordance with article 17.3 of Regulation (EC) No 1332/2008 on food enzymes.

1.2 Interpretation of the Terms of Reference

The present scientific opinion addresses the European Commission's request to carry out the safety assessment of food enzyme maltogenic amylase from a genetically modified B. licheniformis (strain DP‐Dzr50).

2 Data and methodologies

2.1 Data

The applicant has submitted a dossier in support of the application for authorisation of the food enzyme maltogenic amylase from a genetically modified B. licheniformis (strain DP‐Dzr50).

Additional information was sought from the applicant during the assessment process in a request from EFSA sent on 20 March 2019 and was consequently provided (see ‘documentation provided to EFSA’).

2.2 Methodologies

The assessment was conducted in line with the principles described in the EFSA ‘Guidance on transparency in the scientific aspects of risk assessment’ (EFSA, 2009b) as well as in the ‘Statement on characterisation of microorganisms used for the production of food enzymes’ (EFSA CEP Panel, 2019) and following the relevant existing guidance of EFSA Scientific Committee.

The current ‘Guidance on the submission of a dossier on food enzymes for safety evaluation’ (EFSA, 2009a) has been followed for the evaluation of the application with the exception of the exposure assessment, which was carried out in accordance to the methodology described in the ‘CEF Panel statement on the exposure assessment of food enzymes’ (EFSA CEF Panel, 2016).

3 Assessment

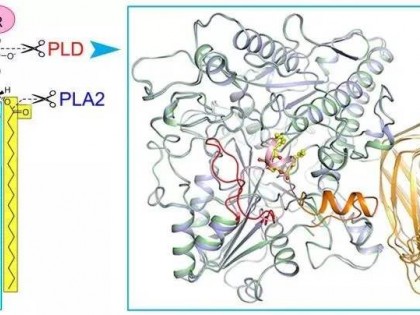

IUBMB nomenclature: Glucan 1,4‐α‐maltohydrolase

Systematic name: 4‐α‐D‐glucan α‐maltohydrolase

Synonyms: Maltogenic amylase, maltogenic α‐amylase

IUBMB No: EC 3.2.1.133

CAS No: 160611‐47‐2.

The maltogenic amylase catalyses the hydrolysis of (1→4)‐α‐d‐glucosidic linkages in starch polysaccharides, to successively remove maltose residues from the non‐reducing ends of the chains. It is intended to be used in baking and brewing processes, distilled alcohol production and starch processing for the production of glucose syrups.

3.1 Source of the food enzyme4

The maltogenic amylase is produced with the genetically modified B. licheniformis strain DP‐Dzr50 (■■■■■),5 which is deposited in the Westerdijk Fungal Biodiversity Institute (CBS) with the deposit number ■■■■■.6

3.1.1 Characteristics of the parental and recipient microorganisms

The parental strain B. licheniformis ■■■■■ was identified as B. licheniformis ■■■■■7

The recipient strain B. licheniformis ■■■■■ was developed from the parental strain ■■■■■

■■■■■

3.1.2 Characteristics of the introduced sequences

■■■■■

■■■■■

3.1.3 Description of the genetic modification process

The purpose of genetic modification was to enable the production strain to synthesise maltogenic amylase ■■■■■

3.1.4 Safety aspects of the genetic modification

The technical dossier contains all necessary information on the recipient microorganism, the donor organism and the genetic modification process.

The recipient strain B. licheniformis ■■■■■

The production strain B. licheniformis DP‐Dzr50 ■■■■■

■■■■■8

Genotypic stability of the B. licheniformis DP‐Dzr50 production strain was demonstrated ■■■■■10

Besides the presence of ■■■■■ copies of the ■■■■■ gene, no other issues of concern arising from the genetic modifications were identified by the Panel.

3.2 Production of the food enzyme

The food enzyme is manufactured according to the Food Hygiene Regulation (EC) No. 852/200411, with food safety procedures based on Hazard Analysis and Critical Control Points (HACCP) and in accordance with current Good Manufacturing Practice (GMP).12

The production strain is grown as a pure culture using a typical industrial medium in a submerged, batch or fed‐batch fermentation system with conventional process controls in place. After completion of the fermentation, the solid biomass is removed from the fermentation broth by filtration leaving a supernatant containing the food enzyme. The filtrate containing the enzyme is then further purified and concentrated, including an ultrafiltration step in which enzyme protein is retained, while most of the low molecular weight material passes the filtration membrane and is discarded.13 The applicant provided information on the identity of the substances used to control the fermentation and in the subsequent downstream processing of the food enzyme.14

The Panel considered that sufficient information has been provided on the manufacturing process and the quality assurance system implemented by the applicant to exclude issues of concern.

3.3 Characteristics of the food enzyme

3.3.1 Properties of the food enzyme

The maltogenic amylase is a single polypeptide chain of ■■■■■ amino acids.15 The molecular mass of the mature protein, derived from the amino acid sequence, was calculated to be ■■■■■ kDa.16 The food enzyme was investigated by sodium dodecyl sulfate–polyacrylamide gel electrophoresis (SDS–PAGE). A consistent protein pattern was observed across all batches. The gel showed a single major protein band corresponding to an apparent molecular mass of about ■■■■■ kDa. No other enzymatic side activities were reported.

The in‐house determination of the maltogenic amylase activity is based on the hydrolysis of the substrate p‐nitrophenyl‐maltotrioside, (reaction conditions: pH 5.6, temperature 37°C, reaction time 120 min). The enzymatic activity is determined by measuring the release of p‐nitrophenol spectrophotometrically at 405 nm. One unit of maltogenic amylase activity (BU) corresponds to the amount of enzyme that produces 1 μmol glucose per minute under the conditions of the assay.17

The food enzyme has a temperature optimum around 50°C (pH 5.2) and a pH optimum between 4.5 and 6.0 (temperature 50°C).18 Thermostability was tested after a pre‐incubation of the food enzyme for 30 min at different temperatures. Under the conditions (pH 5.2) of the applied temperature stability assay, the maltogenic amylase activity decreased above 50°C showing no residual activity above 80°C.

3.3.2 Chemical parameters

Data on the chemical parameters of the food enzyme were provided for four food enzyme batches, three batches used for commercialisation and one batch produced for the toxicological tests (Table 1). The average Total Organic Solids (TOS) of the three food enzyme batches for commercialisation was 14.7%. The average enzyme activity/TOS ratio of the three food enzyme batches for commercialisation was 325 BU/mg TOS.

| Parameter | Unit | Batches | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4a | ||

| Maltogenic amylase activity | BU/g batchb | 47,407 | 38,701 | 56,603 | 36,249 |

| Protein | % | 9.81 | 5.74 | 10.78 | 6.67 |

| Ash | % | 2.12 | 2.18 | 1.49 | 1.04 |

| Water | % | 81.90 | 86.52 | 81.73 | 89.33 |

| Total Organic Solids (TOS)c | % | 15.98 | 11.30 | 16.78 | 9.63 |

| Activity/mg TOS | BU/mg TOS | 297 | 342 | 337 | 376 |

- a Batch used for the toxicological studies.

- b BU/g: maltogenic amylase units/g (see Section 3.3.1).

- c TOS calculated as 100% ‐ % water ‐ % ash.

3.3.3 Purity

The lead content in the three commercial batches was below 0.05 mg/kg19,20 and in the batch used for toxicological studies below 5 mg/kg21,22 which complies with the specification for lead (≤ 5 mg/kg) as laid down in the general specifications and considerations for enzymes used in food processing (FAO/WHO, 2006). In addition, the levels of arsenic, mercury and cadmium23 in the batch used for toxicological testing were below the limits of detection of the employed methodologies.24

The food enzyme complies with the microbiological criteria25 as laid down in the general specifications and considerations for enzymes used in food processing (FAO/WHO, 2006), which stipulate that E. coli and Salmonella species are absent in 25 g of sample and total coliforms should not exceed 30 colony forming unit (CFU) per gram. No antimicrobial activity was detected in any of these batches (FAO/WHO, 2006).26

The Panel considered that the information provided on the purity of the food enzyme is sufficient.

3.3.4 Viable cells and DNA of the production strain

The absence of the production strain in the food enzyme was demonstrated in nine independent batches in duplicate. ■■■■■27 The results were negative.

A test for recombinant DNA in the food enzyme was made by polymerase chain reaction (PCR) analysis of three batches in triplicate. No DNA was detected ■■■■■28

3.4 Toxicological data

A battery of toxicological tests including a bacterial gene mutation assay (Ames test), an in vitro mammalian chromosomal aberration test, and a repeated dose 90‐day oral toxicity study in rats has been provided. The batch 4 (Table 1) used in these studies has a slightly higher activity/mg TOS than the three batches for commercialisation However, this value was still comparable to those of the commercial batches and thus batch 4 was considered suitable for toxicological testing.

3.4.1 Genotoxicity

3.4.1.1 Bacterial reverse mutation test

A bacterial reverse mutation assay (Ames test) was performed according to Organisation for Economic Co‐operation and Development (OECD) Test Guideline 471 (OECD, 1997a) and following Good Laboratory Practice (GLP) in four strains of Salmonella Typhimurium (TA1535, TA1537, TA98 and TA100) and E. coli WP2uvrA, in the presence or absence of metabolic activation (S9 mix).29 Two experiments were carried out using five different concentrations of the food enzyme (50, 150, 500, 1,500 and 5,000 μg food enzyme/plate, corresponding to 7.23, 21.7, 72.3, 217 and 723 μg TOS/plate) (batch 4). In the first experiment, the direct plate incorporation and, in the second experiment, the pre‐incubation methods were applied. No evidence of toxicity or precipitate was observed under any of the conditions tested. In the first experiment, a statistically significant increase in number of revertant colonies was observed at the concentration of 5,000 μg food enzyme/plate in TA100 and 150 and 1,500 μg food enzyme/plate in TA1535 in the presence of S9 mix only. These increases were not reproduced in the second experiment and were within historical control range. Therefore, the Panel concluded that the food enzyme maltogenic amylase did not induce gene mutations in the bacterial reverse mutation assay under the test conditions employed for this study.

3.4.1.2 In vitro mammalian chromosomal aberration test

The in vitro mammalian chromosome aberration test was carried out according to the OECD Test Guideline 473 (OECD, 1997b) and following GLP in cultured human peripheral blood lymphocytes.30 Two experiments were performed. In the first experiment, applying 4 h treatment + 20 h recovery, the cultures were exposed to concentrations of 2,500, 3,750 and 5,000 μg food enzyme/mL (corresponding to 361, 542 and 723 μg TOS/mL) in the absence of the S9 mix and 1,250, 2,500 and 5,000 μg food enzyme/mL (corresponding to 181, 361 and 723 μg TOS/mL) in the presence of the S9 mix. In the second experiment, applying continuous 24 h treatment without S9 mix, the cultures were exposed to concentrations of 25, 50 and 75 μg food enzyme/mL (corresponding to 3.61, 7.23 and 10.8 μg TOS/mL) and for 4 h treatment + 20 h recovery with the S9 mix, the concentrations tested were 1,250, 2,500 and 5,000 μg food enzyme/mL (corresponding to 181, 361 and 723 μg TOS/mL) (batch 4). Cytotoxicity, reported as inhibition of mitotic index (34% reduction with respect to the control), was observed in long‐term treatment experiment without S9 mix. For all food enzyme concentrations used, the frequency of cells with chromosomal aberrations was similar to that of negative controls. No significant increase in the frequency of polyploid cells was observed. The Panel concluded that the food enzyme maltogenic amylase did not induce structural and numerical chromosomal aberrations in cultured human peripheral blood lymphocytes when tested up to 5,000 μg food enzyme/mL (corresponding to 723 μg TOS/mL) under the experimental conditions employed for this study.

Therefore, the Panel concluded that on the basis of the in vitro studies there is no concern for genotoxicity for the maltogenic amylase tested.

3.4.2 Repeated dose 90‐day oral toxicity study in rodents

A repeated dose 90‐day oral toxicity study in rodents was performed according to OECD Test Guideline 408 (OECD, 1998) and following GLP.31 Groups of 10 male and 10 female Wistar Han™: RccHan™: WIST rats received the food enzyme by gavage in doses of 20, 40 and 80 mg TOS/kg bw per day. Controls received the vehicle (0.9% saline).

No mortality was observed.

Clinical observations revealed a damaged tail (days 82–90) and corneal opacity in the left eye of one high‐dose male throughout the treatment period, with a dry appearance and small scab formation of the eye lids, recorded during the pretreatment ophthalmoscopic examination and the first 3 days of treatment. These findings were considered by the Panel as incidental.

A statistically significant reduction in body weight gains in low‐dose males (week 7) and a statistically significant increase in body weight gains in mid‐dose and high‐dose males (week 8) when compared to controls were recorded. The Panel noted, however, that the overall body weights for treated animals were not adversely affected.

Functional observations showed slight but statistically significant increases in hind limb grip strength for two out of three tests and a reduction in overall motor activity in high‐dose females when compared to controls. The Panel noted that these findings were limited to one sex and occurred in absence of any clinical signs of disturbed clinical condition. Therefore, the Panel considered these findings as incidental and not of toxicological significance.

Among haematology parameters, a statistically significant reduction in activated partial thromboplastin time (APTT) in high‐dose males, when compared to controls, was recorded. The Panel considered this change as non‐adverse, as the prothrombin time was not statistically significantly changed in this treated group.

Necropsy revealed a reddened thymus in one low‐dose female, a fluid‐filled sac in the brain from another low‐dose female, a fluid‐filled sac in the kidneys in one high‐dose female, and reddened lungs in two control females and one mid‐dose female. In the absence of any related microscopic changes, these findings were considered by the Panel as incidental.

No other statistically significant differences to controls were observed.

The Panel identified a no observed adverse effect level (NOAEL) of 80 mg TOS/kg bw per day, the highest dose tested.

3.4.3 Allergenicity

The allergenicity assessment considers only the food enzyme and not any carrier or other excipient, which may be used in the final formulation.

The potential allergenicity of the maltogenic amylase produced with the genetically modified B. licheniformis strain DP‐Dzr50 was assessed by comparison of its amino acid sequence with those of known allergens according to the scientific opinion on the assessment of allergenicity of genetically modified plants and microorganisms and derived food and feed of the Scientific Panel on Genetically Modified Organisms (EFSA GMO Panel, 2010). Using higher than 35% identity in a sliding window of 80 amino acids as criterion, three matches were found. ■■■■■32

No information is available on oral sensitisation or elicitation reactions of this maltogenic amylase.

■■■■■ However, several studies have shown that adults with occupational asthma caused by a food enzyme (as described for ■■■■■) can ingest respiratory allergens without acquiring clinical symptoms of food allergy (Cullinan et al., 1997; Poulsen, 2004; Armentia et al., 2009). ■■■■■

According to the information provided, substances or products that may cause allergies or intolerances (Regulation EU 1169/201133) are used as raw materials (■■■■■)34 in the growth medium of the production organism. However, during the fermentation process, these substances will be degraded and utilised by the bacterium for cell growth, cell maintenance and production of enzyme. In addition, the microbial biomass and fermentation solids are removed. Taking into account the fermentation process and downstream processing, the Panel considered that potentially allergenic residues of these foods employed as protein sources are not expected to be present.

Quantifying the risk for allergenicity is not possible in view of the individual susceptibility to food allergens. Allergenicity can be ruled out only if the proteins are fully removed as is the case for distilled alcohol production. In the starch processing for the production of glucose syrups, experimental data showed a significant removal (> 99%) of protein. However, traces of protein could be present in glucose syrup. The food enzyme remains in the beer and baked products.

The Panel considered that, under the intended conditions of use, the risk of allergic sensitisation and elicitation reactions upon dietary exposure to this food enzyme can be excluded for distilled alcohol production. The risk cannot be excluded for starch processing, baking and brewing processes but the likelihood of such reactions to occur is considered to be low.

3.5 Dietary exposure

3.5.1 Intended use of the food enzyme

The food enzyme is intended to be used in four food manufacturing processes at the recommended use levels summarised in Table 2.35

| Food manufacturing processa | Raw material | Recommended dosage of the food enzyme |

|---|---|---|

| Baking processes | Flour | Up to 5.07 mg TOS/kg flour |

| Brewing processes | Cereals | Up to 40 mg TOS/kg cereal |

| Distilled alcohol production | Cereals | Up to 40 mg TOS/kg cereal |

| Starch processing for the production of glucose syrups | Starch | Up to 40 mg TOS/kg starch |

- TOS: Total Organic Solids.

- a The description provided by the applicant has been harmonised by EFSA according to the ‘EC working document describing the food processes in which food enzymes are intended to be used’ − not yet published at the time of adoption of this opinion.

In baking processes, the food enzyme performs its technological function during dough or batter handling, contributing to an improved and consistent baking process. The conversion of starch lowers the rate of starch retrogradation, thereby reducing staling, and improves crumb structure. based on data provided on thermostability (see Section 3.3.1), it is expected that the maltogenic amylase is inactivated during the baking step.

In brewing processes, the food enzyme is added in the mashing step, where it will hydrolyze the starchy content of the mash into fermentable sugars, i.e. maltose. The more uniform formation of fermentable sugars improves yield and consistency of the products. based on data provided on thermostability (see Section 3.3.1), it is expected that the maltogenic amylase is inactivated during brewing processes.

In distilled alcohol production, the food enzyme is added in the pretreatment, liquefaction and/or pre‐saccharification steps.

In starch processing for glucose syrups production, the food enzyme is added during the saccharification step.

Experimental data have been provided on the removal (> 99%) of protein in the course of distilled alcohol production and starch processing for the production of glucose syrups (documentation provided to EFSA No°3). The Panel considered the evidence as sufficient to conclude that residual amounts of TOS (including substances other than proteins) are removed by distillation. In addition, taking into account the purification steps applied to the production of glucose syrups, i.e. filtration, ion exchange chromatography, treatment with active carbon, the Panel also considers that the amount of TOS in the final glucose syrup will be removed to a similar degree.

3.5.2 Dietary exposure estimation

As residual amounts of TOS are removed by distillation and by the purification steps applied during the production of glucose syrups (by > 99%), foods/ingredients derived by these two processes, i.e., distilled alcohols and glucose syrups were excluded from the estimation.

For and baking and brewing processes, chronic exposure was calculated using the methodology described in the CEF Panel statement on the exposure assessment of food enzymes (EFSA CEF Panel, 2016). The assessment involved selection of relevant food categories from the EFSA Comprehensive European Food Consumption Database36 and application of process and technical conversion factors (Annex B in EFSA CEF Panel, 2016).

Chronic exposure was calculated by combining the maximum recommended use level provided by the applicant (see Table 2) with the relevant FoodEx categories (Annex B in EFSA CEF Panel, 2016), based on individual consumption data. Exposure from individual FoodEx categories was subsequently summed up, averaged over the total survey period and normalised for body weight. This was done for all individuals across all surveys, resulting in distributions of individual average exposure. based on these distributions, the mean and 95th percentile exposures were calculated per survey for the total population and per age class. Surveys with only one day per subject were excluded and high‐level exposure/intake was calculated for only those population groups in which the sample size was sufficiently large to allow calculation of the 95th percentile (EFSA, 2011).

Table 3 provides an overview of the derived exposure estimates across all surveys. Detailed average and 95th percentile exposure to the food enzyme‐TOS per age class, country and survey, as well as contribution from each FoodEx category to the total dietary exposure are reported in Appendix A – Tables 1 and 2. For the present assessment, food consumption data were available from 35 different dietary surveys (covering infants, toddlers, children, adolescents, adults and the elderly), carried out in 22 European countries (Appendix B).

| Estimated exposure (mg TOS/kg body weight per day) | ||||||

|---|---|---|---|---|---|---|

| Population group | Infants | Toddlers | Children | Adolescents | Adults | The elderly |

| Age range | ||||||

| Min–max mean (number of surveys) | 0.001–0.014 (10) | 0.011–0.030 (14) | 0.013–0.029 (19) | 0.008–0.021 (18) | 0.009–0.052 (19) | 0.009–0.029 (18) |

| Min–max 95th percentile (number of surveys) | 0.006–0.060 (8) | 0.027–0.052 (12) | 0.024–0.055 (19) | 0.015–0.060 (17) | 0.030–0.199 (19) | 0.020–0.096 (18) |

- TOS: total organic solids.

3.5.3 Uncertainty analysis

In accordance with the guidance provided in the EFSA opinion related to uncertainties in dietary exposure assessment (EFSA, 2007), the following sources of uncertainties have been considered and are summarised in Table 4.

| Sources of uncertainties | Direction of impact |

|---|---|

| Model input data | |

| Consumption data: different methodologies/representativeness/underreporting/misreporting/no portion size standard | +/− |

| Use of data from food consumption survey of a few days to estimate long‐term (chronic) exposure for high percentiles (95th percentile) | + |

| Possible national differences in categorisation and classification of food | +/− |

| FoodEx categories included in the exposure assessment were assumed to always contain the food enzyme–TOS | + |

| Exposure to food enzyme–TOS was always calculated based on the recommended maximum use level | + |

| Selection of broad FoodEx categories for the exposure assessment | + |

| Use of recipe fractions in disaggregation FoodEx categories | +/− |

| Use of technical factors in the exposure model | +/− |

| Exclusion of two processes (distilled alcohol production and starch processing for the production of glucose syrups) from the exposure assessment | − |

- TOS: total organic solids.

- +: uncertainty with potential to cause overestimation of exposure; −: uncertainty with potential to cause underestimation of exposure.

The conservative approach applied to the exposure estimate to food enzyme–TOS, in particular assumptions made on the occurrence and use levels of this specific food enzyme, is likely to have led to a considerable overestimation of the exposure.

The exclusion of distilled alcohol production and starch processing for the production of glucose syrups from the exposure assessment was based on > 99% of TOS removal during both processes and is not expected to have an impact on the overall estimate derived.

3.6 Margin of exposure

A comparison of the NOAEL (80 mg TOS/kg bw per day) from the 90‐day study with the derived exposure estimates in six human population groups of 0.001–0.052 mg TOS/kg bw per day at the mean and from 0.006 to 0.199 mg TOS/kg bw per day at the 95th percentile, resulted in margins of exposure (MOEs) above 402 indicating that there is no safety concern.

4 Conclusions

based on the data provided, the removal of TOS during distilled alcohol production and starch processing for the production of glucose syrups and the margin of exposure calculated when used in baking and brewing processes, the Panel concludes that the food enzyme maltogenic amylase produced with the genetically modified B. licheniformis strain DP‐Dzr50 does not give rise to safety concerns under the intended conditions of use.

The production strain of the food enzyme contains multiple copies of a known antimicrobial resistance gene. However, based on the absence of viable cells and DNA from the production organism in the food enzyme, this is not considered to be a risk.

documentation provided to EFSA

- Dossier “Application for authorisation of glucan 1,4‐α‐maltohydrolase from a genetically modified strain of Bacillus licheniformis DP‐Dzr50 in accordance with Regulation (EC) No 1331/2008”, January 2016. Submitted by Danisco US Inc.

- Additional information was received from Danisco US Inc. in September 2019.

- Additional information on “Food enzyme removal during the production of cereal based distilled alcoholic beverages” and “Food enzyme carry/over in glucose syrups”. February 2017. Provided by the Association of Manufacturers and Formulators of Enzyme Products.